REAL-fit Project News

Optimisation of welding processes

In the Laboratory for welding, under the supervision of Prof. Ivica Garašić from the Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, we optimise welding processes for different aluminium alloys.

Developed welding procedures comply with EN 1090-3, and the AC and DC processes are optimised for butt and fillet welds with and without preparations on the aluminium parent material.

Discussion group ‘Engineering structures’ 2024

Two interesting topics from the REAL-fit project were presented on 13 September 2024 at the Discussion group ‘Engineering structures’ of the Department for Structures, Faculty of Civil Engineering of the University of Zagreb:

Ivan Čudina: Numerical analyses of the influence of imperfections on the buckling resistance of longitudinally welded aluminium compression members

Anđelo Valčić: Direct design method for aluminium frame structures

Preliminary results of the mechanical properties

On 17 July 2024, a meeting on the preliminary results of the mechanical properties of the base material and welded specimens was held at the Laboratory for welding at the University of Zagreb, Faculty of Mechanical Engineering and Naval Architecture.

We have six different types of aluminium plates (2 alloys in 3 different thicknesses each), which allow a variety of interesting combinations with different welding parameters.

There are still many open questions, but with micro and macro tests we are getting good arguments for the development of optimised welding procedures.

ICSAS 24 – Rio de Janeiro, Brazil

We are excited to share that our research paper, ‘Towards the System-Based Design of Aluminium Portal Frames’, was presented at the 10th International Conference on Steel and Aluminium Structures in Rio de Janeiro, Brazil, from June 5-7, 2024. The presentation was delivered by Anđelo Valčić, a teaching and research assistant at the Chair for Metal Structures, Faculty of Civil Engineering, University of Zagreb.

This pioneering research, co-authored with Itsaso Arrayago from Universitat Politécnica de Catalunya and Davor Skejić from the Faculty of Civil Engineering, University of Zagreb, marks a significant step in exploring the synergy between system-based design principles and aluminium.

Seminar ALUMINIUM AND ALUMINIUM ALLOYS AS A CONSTRUCTION MATERIAL, Zagreb, 13.05.2024.

Around fifty participants, top-class experts in the field of metal structures, were an exceptional audience for the topics of the seminar ALUMINIUM AND ALUMINIUM ALLOYS AS A CONSTRUCTION MATERIAL, organised by the Croatian Society for Material Protection and the Chair of Material Protection (FSB, Zagreb) on 13 May 2024.

Under the direction of Prof. Ivan Juraga, 11 topics closely related to the properties, welding, corrosion behaviour, heat treatment and problems in the application of aluminium alloys were presented. Prof. Davor Skejić had the honour of presenting a topic entitled ‘Development of European standards for the design of aluminium structures – HRZZ project REAL-fit’, in which he presented the idea and current status of the REAL-fit project in addition to the innovations brought about by the second generation of Eurocode 9.

Presentation of the project

The REAL-fit project was presented in the Journal for Welding and Allied Techniques – WELDING 67 (2024) 1/2. The journal Welding has been published since 1958 and is one of the oldest technical journals in Croatia. It is published by the Croatian Society for Welding Technology and employees from the University of Zagreb, Faculty of Mechanical Engineering and Naval Architecture, are involved in its publication.

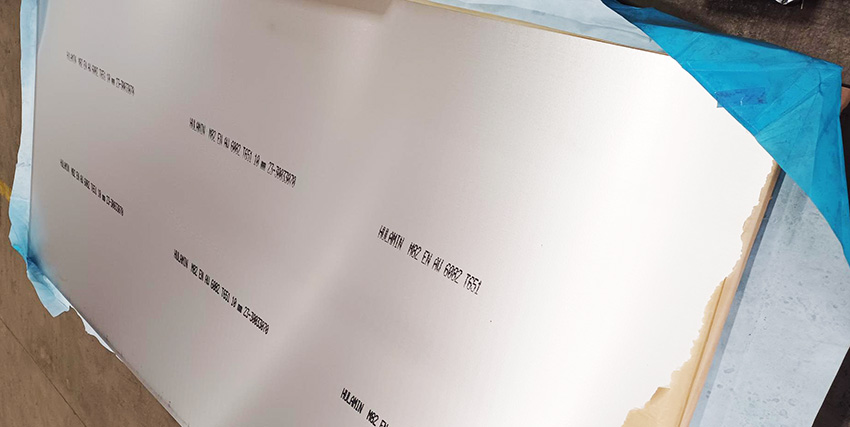

Material for laboratory specimens

In March 2024, we purchased six types of aluminium plates, two different alloys in three different thicknesses each, which we will use during the REAL-fit project.

We are looking forward to testing their mechanical properties and chemical compositions.

Kick-off meeting

On 16 January 2024, the kick-off meeting of the REAL-fit project took place at the Faculty of Civil Engineering, University of Zagreb.

In addition to the presentation of the project, a detailed analysis of the work plan was also carried out.

An interdisciplinary working group consisting of 10 members from 3 different institutions was officially formed. This will bring together experts from the field of aluminium structures and the specific field of aluminium welding.